Understanding Laser Engraving on Steel

What is Laser Engraving?

Laser engraving on steel is transforming the way artisans, manufacturers, and hobbyists approach surface decoration and customization. It’s a delicate dance between precision and artistry, where the laser beam acts as a painter’s brush but with unparalleled accuracy. When executed correctly, laser engraver on steel can produce intricate designs that are both durable and aesthetically compelling, making it a preferred choice for high-end branding and bespoke creations.

What exactly is laser engraving? At its core, it’s a process that uses focused light energy to etch or carve into hard materials like steel. Unlike traditional techniques, laser engraving offers a non-contact method, eliminating the risk of physical deformation or damage. This technology can engrave text, images, or complex patterns with razor-sharp detail, often in a fraction of the time it takes with manual methods. The unique advantage of a laser engraver on steel lies in its ability to produce consistent, high-quality results on a variety of steel surfaces, from jewelry to industrial tools.

For those seeking precision, here’s a quick overview of what makes laser engraver on steel so effective:

- High-resolution control over the depth and detail of the engravings.

- Versatility to customize designs with minimal setup time.

- Exceptional durability of the markings, resistant to wear and corrosion.

Advantages of Using Laser Engraving on Steel

In a landscape where craftsmanship increasingly intersects with technological innovation, the laser engraver on steel offers a profound leap forward. Its capacity to produce intricate, permanent markings on steel surfaces—ranging from bespoke jewelry to industrial components—is nothing short of revolutionary. The beauty of this technology lies in its ability to marry artistry with durability, creating engravings that withstand the test of time and environmental wear.

One of the most compelling advantages of using a laser engraver on steel is the precision it affords. The controlled laser beam can carve delicate details and complex patterns with razor-sharp accuracy, reducing errors and waste. Additionally, the process is remarkably fast, making it ideal for high-volume production or customized projects. The engravings are not only visually striking but also resistant to corrosion and abrasion, ensuring lasting quality in demanding South African climates and applications.

Moreover, laser engraving on steel opens doors to a spectrum of creative and functional possibilities. From personalized gifts to industrial branding, the technology’s versatility is unmatched. Whether one seeks to etch a subtle logo or a detailed artwork, the laser engraver on steel provides a seamless solution—transforming ordinary surfaces into extraordinary statements of craftsmanship and innovation. This fusion of art and engineering continues to redefine what is possible in surface decoration and surface marking today.

Types of Steel Suitable for Laser Engraving

Understanding which types of steel are suitable for laser engraving is crucial for achieving precise, durable results. Not all steel reacts the same way to a laser engraver on steel, and choosing the right grade can make all the difference. Generally, carbon steels and stainless steels are the most compatible, offering clean, sharp markings that withstand wear and corrosion.

Stainless steel, especially grades like 304 and 316, are popular choices because they provide excellent engraving contrast and resistance to environmental factors. Carbon steels, such as 1018 or 1045, are also frequently used due to their affordability and ease of engraving. When selecting steel for laser engraving, consider the thickness and surface finish, as these factors influence the engraving quality and speed.

- Type of steel: Opt for stainless or carbon steel based on application and budget.

- Surface condition: Smooth, clean surfaces yield the best results with a laser engraver on steel.

- Thickness: Thinner steel sheets are easier to engrave but ensure the thickness suits your project needs.

Understanding these nuances helps maximize the potential of a laser engraver on steel, ensuring each mark is both visually striking and enduring. This technology unlocks a new level of precision for South African industries, from jewelry to industrial parts, all while maintaining quality and longevity.

Choosing the Right Laser Engraver for Steel

Types of Laser Engravers

Choosing the right laser engraver for steel is a pivotal decision that can transform raw metal into a canvas of intricate artistry or precise branding. In South Africa, where craftsmanship is deeply rooted in tradition yet eager for modern innovation, selecting a laser engraver on steel that matches your needs is essential. The market offers a variety of options, each suited to different steel types and engraving complexities.

Whether you’re working with mild steel, stainless steel, or more specialized alloys, understanding the nuances of laser engravers is crucial. For instance, fiber laser engravers excel at marking stainless steel with high precision and minimal thermal distortion, making them ideal for detailed and durable engravings. On the other hand, CO2 laser engravers, while less common for steel, can be effective with specific settings and proper focus.

When choosing a laser engraver on steel, consider these factors:

- Power output, which influences engraving depth and speed

- Wavelength compatibility with steel types

- Size of the engraving bed for accommodating different project scales

- Ease of operation and maintenance, especially in rural workshops

Ultimately, the right choice hinges on the steel types you intend to work with and the quality of finish desired—each project telling its own story through the laser’s precise touch.

Key Features to Consider

Choosing the right laser engraver on steel is akin to selecting a finely tailored suit—each detail matters profoundly. The key features to consider should align with the nuances of your project, ensuring precision and durability. Power output, for instance, directly influences how deep and quickly your design is etched—no one wants a hurried job that flattens the finesse. Wavelength compatibility is equally vital; not all laser engravers on steel are created equal, especially when dealing with different steel alloys.

Size matters too, especially if your workshop in South Africa needs to accommodate larger or more intricate projects. An appropriately sized engraving bed keeps workflow seamless and avoids unnecessary frustration. Ease of operation and maintenance also shouldn’t be overlooked—after all, a laser engraver on steel is an investment, and simplicity ensures longevity. Whether you’re marking stainless steel or mild steel, the features you prioritize will dictate the craftsmanship and efficiency of your engravings.

Budget and Cost Considerations

In the world of precision craftsmanship, investing in a laser engraver on steel requires a keen eye not just for quality but also for cost efficiency. With the right balance, you can unlock remarkable results without breaking the bank. Budget considerations are often the first hurdle, but they shouldn’t be the sole determinant—value and durability must also be part of the equation.

Understanding the true cost of a laser engraver on steel involves more than initial purchase price. Operational expenses such as maintenance, consumables, and power consumption play a vital role in long-term affordability. It’s wise to evaluate models that offer robust build quality and reliable performance, ensuring your investment stands the test of time.

When selecting a laser engraver on steel within your budget, consider prioritizing features like adjustable power settings and wavelength compatibility. These elements influence the versatility and precision of your engravings, especially when working with different steel alloys. Remember, choosing a model that aligns with your project scope and future growth can save you money and frustration down the line. After all, the most economical option isn’t always the cheapest—it’s the one that delivers consistent, high-quality results while fitting comfortably within your financial plan.

Preparing Steel for Laser Engraving

Cleaning and Surface Preparation

Before the mesmerizing dance of laser light begins its symphony on steel, the surface must be primed for its moment in the spotlight. A pristine, well-prepared steel surface transforms the laser engraver on steel into a vessel of intricate artistry, ensuring each etch is sharp, vivid, and enduring. The secret lies in meticulous cleaning—removing oils, fingerprints, and any trace of oxidation that might dull the laser’s precision.

Surface preparation isn’t merely about cleanliness; it’s about creating a canvas that embraces the laser’s energy with unwavering fidelity. Light abrasive polishing can enhance the surface’s reflectivity, allowing the laser to focus its energy more effectively. For those seeking perfection, a thorough cleaning with isopropyl alcohol or specialized degreasers can elevate the engraving quality to legendary status. Remember, a surface free of contaminants acts as a gateway for the laser engraver on steel to unlock its full potential—crafting designs that are as resilient as the steel itself!

Choosing the Right Steel Finish

Choosing the right steel finish is crucial to maximize the potential of your laser engraver on steel. A smooth, uniform surface helps the laser focus its energy precisely, producing cleaner, sharper engravings. Different finishes can influence how the laser interacts with the material, impacting depth and clarity. For example, matte finishes tend to absorb laser light more effectively, resulting in more defined engravings, while highly polished surfaces reflect more light, which can diminish detail.

When preparing steel for laser engraving, consider the specific application. Sometimes, a simple abrasive polish is enough to enhance surface reflectivity, but in other cases, a more refined surface may be necessary. To tailor your approach, you might use:

- Sandblasted finishes for a textured background

- Brushed finishes for a subtle, modern look

- Electroplated coatings for added durability

Each type of finish offers unique advantages, so understanding the desired outcome guides the selection process. A carefully chosen steel finish not only amplifies the laser engraver on steel’s capabilities but also ensures your designs stand the test of time with impeccable detail and resilience.

Design Files and Graphics Preparation

Preparing steel for laser engraving is an art in itself, an often overlooked prelude that can make or break the final masterpiece. With over 80% of high-quality laser engraver on steel projects relying on meticulous preparation, understanding the nuances becomes essential. A clean, well-prepared surface ensures the laser’s focus remains sharp, translating into crisp, detailed engravings that command attention.

Before diving into the design files, it’s wise to assess the steel’s surface. A smooth, uniform finish allows the laser to interact with the material more predictably, minimizing distortion or uneven engraving. Sometimes, a simple wipe with a lint-free cloth suffices; other times, a more involved process—such as light sanding or applying a specific coating—may be necessary.

When it comes to graphics preparation, clarity is king. Vector files, with their crisp lines and scalable precision, are ideal for laser engraver on steel. Ensuring your design has high contrast and appropriate line weights will help the laser focus and produce the finest detail. For added finesse, consider using a raster engraving mode for shaded areas, giving depth and texture to your project. A seamless blend of well-prepared steel and thoughtfully crafted design files elevates the entire process, transforming steel into a canvas for artistry and craftsmanship that will endure through generations.

Laser Engraving Process on Steel

Step-by-Step Engraving Procedure

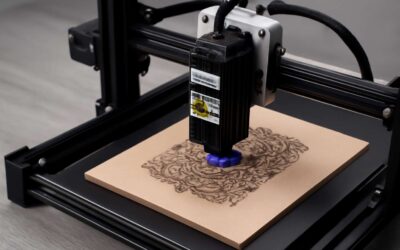

The laser engraving process on steel is a fascinating blend of precision technology and creative craftsmanship. When executed correctly, it transforms cold, unyielding metal into a canvas of intricate designs—each stroke capturing fine details with remarkable accuracy. The step-by-step engraving procedure begins with selecting a suitable steel surface, ensuring it’s clean and free of debris to maximize the laser’s effectiveness. Next, the design files are uploaded into the laser engraver on steel, which interprets the digital image into a series of focused pulses of light.

During engraving, the laser beam meticulously etches into the steel surface, either by removing material or changing its surface properties, depending on the desired effect. For optimal results, parameters such as laser power, speed, and frequency are carefully calibrated. This process not only guarantees sharp, durable markings but also preserves the integrity of the steel, making it ideal for industrial purposes or personalized craftsmanship. The precision of a laser engraver on steel ensures each project stands out, whether for branding, decorative art, or functional markings. The meticulous execution of this step-by-step process results in stunning, long-lasting engravings that elevate any steel surface into a work of art.

Optimizing Settings for Quality Output

Optimizing the settings on a laser engraver on steel is akin to tuning a finely crafted instrument—each parameter must harmonize to produce the masterpiece. Precision in laser power, speed, and frequency is paramount; even a slight deviation can compromise the clarity or durability of the engraving. When configured correctly, these settings allow the laser to carve into steel with exquisite detail, revealing intricate patterns that stand the test of time.

Achieving this delicate balance involves a meticulous calibration process. For instance, lowering the laser speed enhances the depth of engraving, while adjusting the power ensures the steel surface is neither scorched nor under-etched. The key lies in understanding the specific steel type and the desired outcome. Some projects demand a light, decorative etch, while others require deep, permanent markings. For these varied needs, an ordered approach can be invaluable:

- Start with a test sample to determine the ideal laser power and speed.

- Gradually increase the laser intensity until the desired depth and clarity are achieved.

- Adjust the frequency to fine-tune the precision of the engraving, especially for detailed designs.

By meticulously adjusting these parameters, professionals can unlock the full potential of their laser engraver on steel, ensuring each mark is both sharp and enduring, capturing the artistry and resilience that steel embodies. It’s the secret to transforming cold metal into a testament of craftsmanship—an elegant dance between technology and human ingenuity.

Safety Precautions and Best Practices

The precision of a laser engraver on steel hinges not only on the machine’s capabilities but also on unwavering safety protocols. With laser technology capable of etching intricate patterns onto resilient surfaces, the potential hazards become apparent—fumes, intense light emissions, and accidental exposure pose real risks. Ensuring safety isn’t merely a precaution; it’s an essential pillar supporting the artistry and durability of every engraved piece.

Engraving steel with a laser demands rigorous adherence to safety best practices. Protective eyewear rated for specific laser wavelengths, proper ventilation systems, and controlled environments mitigate health risks and safeguard operators. Moreover, understanding the laser’s power settings and avoiding reflective surfaces during operation reduces the chance of unintended laser reflection causing harm.

For optimal safety, consider implementing a systematic approach:

- Ensure all operators undergo comprehensive training on laser safety protocols.

- Regularly inspect and maintain safety equipment and shielding barriers.

- Limit access to the engraving area during operation, maintaining strict control over the environment.

While the allure of creating art on steel is undeniable, respecting the laser’s formidable power remains paramount. This vigilance not only preserves human well-being but also guarantees the integrity of the engraved steel—resulting in a product that stands as a testament to craftsmanship and safety consciousness alike!

Applications and Uses of Laser Engraving on Steel

Personalized Jewelry and Accessories

In the realm of bespoke craftsmanship, the laser engraver on steel has become a conduit for transforming ordinary accessories into timeless treasures. Imagine delicate jewelry, etched with intricate patterns that tell stories of ancestral legends or personal milestones—each piece a testament to artistry powered by advanced laser technology. The applications of laser engraving on steel stretch beyond mere decoration; they serve as symbols of identity and sentiment, capturing the essence of meaningful moments in a lasting form.

Among the most captivating uses are personalized jewelry and accessories that resonate with individuality. From engraved rings bearing initials to custom pendants engraved with meaningful dates, the possibilities are endless. The precision and finesse of a laser engraver on steel enable artisans to craft fine details that would be impossible with traditional methods. Whether creating a unique gift or a branded piece for a corporate event, laser engraving elevates steel jewelry to art. In South Africa, where cultural motifs often inspire design, the laser engraver on steel unlocks a world of creative expression and lasting impressions.

Industrial Marking and Labeling

Laser engraving on steel has revolutionized industrial marking and labeling, offering a durable and precise method for branding and identification. In industries across South Africa, this technology ensures that products are easily traceable, enhancing quality control and compliance with safety standards. The ability to create permanent markings means that labels and codes won’t fade or wear off over time, even under harsh conditions.

Applications of laser engraver on steel extend into various sectors, from manufacturing to logistics. For example, serial numbers, barcodes, and QR codes are engraved directly onto steel components, streamlining inventory management and reducing errors. This process also allows for the customization of warning labels and safety instructions, ensuring clear communication in high-risk environments.

Furthermore, laser engraver on steel can produce intricate logos and artwork for branding purposes. The precision of laser technology enables the inclusion of detailed designs, making each piece unique. Whether for marking industrial tools or creating bespoke corporate gifts, the versatility of laser engraving on steel plays a vital role in modern manufacturing and branding strategies.

Decorative Steel Art and Signage

In the shadowed corridors of modern craftsmanship, the laser engraver on steel emerges as a silent artist—crafting intricate beauty from cold, unyielding metal. Its applications extend beyond mere functionality, venturing into the realm of decorative steel art and signage that whispers stories of resilience and elegance. Imagine a corporate emblem etched with such precision that it becomes an enduring symbol of legacy, or a piece of wall art that captures the eye with its haunting detail. The laser engraver on steel allows artisans to transform steel surfaces into canvases of expressive artistry, blending industrial strength with aesthetic finesse.

From bespoke signage that commands attention to sculptural steel art that evokes emotion, the possibilities are endless. In South Africa’s vibrant landscape of innovation, this technology breathes new life into traditional materials, elevating them into statements of identity and artistry. Whether it’s a commemorative plaque, an ornate sculpture, or a personalized gift that captures the soul of its recipient, the laser engraver on steel makes every creation uniquely compelling.

Customized Corporate Gifts

When it comes to customized corporate gifts that leave a lasting impression, the laser engraver on steel is truly the unsung hero of the modern workshop. Businesses across South Africa are discovering that a sleek, engraved steel item can speak volumes—without uttering a single word. From elegant keychains to sophisticated desk accessories, laser engraving transforms ordinary steel into extraordinary tokens of appreciation and branding. The precision of a laser engraver on steel ensures that every detail, no matter how intricate, is captured flawlessly—making each gift a one-of-a-kind masterpiece.

Using a laser engraver on steel for corporate gifts isn’t just about aesthetics; it’s about creating enduring symbols of loyalty and professionalism. Companies often opt for engraved steel plaques or awards, elevating their recognition programs to a whole new level of sophistication. Want to add a personal touch? Consider monogrammed steel pens or custom nameplates, all crafted with the laser engraver on steel. The possibilities are endless, and the results are always impressive, ensuring your brand remains etched in the minds of clients and partners alike.

Maintenance and Troubleshooting of Laser Engravers on Steel

Routine Maintenance Tips

In the intricate dance of precision and craftsmanship, the laser engraver on steel beckons with a promise of enduring artistry. Yet, even the most sophisticated machinery requires vigilant stewardship; neglect can cast shadows over its luminous potential. Routine maintenance is the silent guardian of quality, ensuring that each etch remains sharp and each cut, pristine. Regularly inspecting the laser lens and mirrors not only preserves the brilliance but also prevents costly downtimes, transforming minor care into monumental savings.

To keep your laser engraver on steel performing at its zenith, adopting a disciplined maintenance regimen is essential. Clean the optics with specialized solvents and lint-free cloths, and ensure the cooling system is free of debris. Additionally, lubricate moving parts according to the manufacturer’s specifications. Troubleshooting often reveals itself through subtle signs—a faint misalignment, inconsistent engraving depth, or unusual noises—each a whisper of underlying issues. Addressing these early can stave off more severe malfunctions and extend the lifespan of your equipment.

For those seeking systematic clarity, consider implementing a structured maintenance schedule.

- Weekly inspection of optics and mirrors

- Monthly calibration checks

- Quarterly deep cleaning of laser components

By treating the laser engraver on steel as a living tool that demands care, operators unlock its fullest potential, transforming mere metal into enduring masterpieces that defy time’s relentless march. Embracing diligent upkeep turns routine tasks into acts of reverence for craftsmanship’s timeless art.

Common Issues and Solutions

Even the most meticulously calibrated laser engraver on steel isn’t immune to the whims of malfunction. When your engraver starts giving you trouble, it’s tempting to throw your hands in the air and curse the technology—trust me, I’ve been there. But often, the root of the issue is a simple misalignment or a dust bunny hiding in the optics. Recognizing common issues early can save you costly downtime and keep your steel engravings razor-sharp.

One of the most frequent culprits is inconsistent engraving depth. This usually indicates that the laser’s focus has drifted or that the mirror alignment is off. Unusual noises are another red flag, often signaling mechanical wear or debris in the cooling system. For those who prefer a systematic approach, I recommend a quick troubleshooting checklist:

- Inspect and clean the laser lens and mirrors regularly.

- Check the cooling system for blockages or leaks.

- Ensure the laser’s focus is correctly calibrated.

Addressing these problems early not only prolongs the lifespan of your laser engraver on steel but also guarantees consistent, high-quality results. Remember, keeping your machine in tip-top shape transforms routine maintenance into a small act of reverence for craftsmanship, ensuring your steel projects remain forever etched in time’s memory.

Laser Engraver Calibration and Upkeep

Maintaining a laser engraver on steel isn’t just about routine cleaning; it’s about preserving the very essence of precision. A well-calibrated machine can transform steel surfaces into works of art, but neglecting upkeep can turn that brilliance into chaos. Regular inspection of the laser’s focus and mirror alignment is paramount—these are the silent guardians of quality. Dust and debris are relentless enemies, silently eroding the clarity of your engravings if left unchecked.

In the realm of troubleshooting, a systematic approach can save hours of frustration. For instance, a quick check of the cooling system can prevent overheating, which often manifests as inconsistent engraving depth or unusual noises. To streamline maintenance, consider this simple list:

- Inspect and clean the laser lens and mirrors thoroughly.

- Check for any cooling system blockages or leaks.

- Calibrate the laser focus to ensure optimal engraving performance.

Addressing these issues promptly ensures your laser engraver on steel remains at peak performance, delivering razor-sharp results every time. When your machine runs smoothly, so does your creativity—free from the shadows of mechanical failure. Remember, each maintenance act is a small step toward eternal craftsmanship, turning steel into timeless masterpieces.

Legal and Safety Considerations

Handling and Operating Laser Equipment Safely

Safety is paramount when handling a laser engraver on steel. These powerful machines emit focused beams that can cause serious injuries if not managed properly. Always wear appropriate protective gear, including laser safety glasses, to shield your eyes from harmful reflections and laser radiation. Ensuring proper ventilation is also critical, as fumes from engraving steel can be hazardous if inhaled over time.

Operators must be trained thoroughly in the laser engraver on steel’s operation and emergency shutdown procedures. Regularly inspecting and maintaining equipment reduces the risk of malfunctions that could lead to accidents. Remember, adherence to legal regulations surrounding laser safety and equipment use isn’t just recommended — it’s mandatory.

- Use certified personal protective equipment (PPE).

- Maintain a clear workspace free of flammable materials.

- Follow manufacturer safety instructions meticulously.

Taking these precautions ensures a safe environment while achieving precise, high-quality results with your laser engraver on steel.

Material Handling Regulations

Operating a laser engraver on steel comes with significant legal and safety responsibilities. Regulations surrounding material handling ensure that both operators and the environment remain protected from potential hazards. In South Africa, adherence to the Occupational Health and Safety Act is not just a formality but a legal mandate that safeguards everyone involved.

Proper handling of steel materials is critical, especially considering the fumes and dust created during engraving. Implementing strict protocols helps prevent accidental exposure and ensures compliance with local environmental standards. A well-established safety plan might include:

- Designated safe zones for operation

- Clear signage warning of laser activity

- Proper disposal procedures for waste fumes and debris

Operators must also be trained thoroughly in the correct use of the laser engraver on steel, including emergency shutdown procedures. Ignoring these legal and safety considerations can lead to severe consequences, both legally and physically, emphasizing the importance of meticulous attention to safety standards in every project involving laser engraving on steel.

Laser Safety Equipment and Precautions

In the realm of laser engraving on steel, safety isn’t just a precaution—it’s a sacred vow that guards both the artisans and the environment. The intense beams emitted by a laser engraver on steel demand respect, as they can cause irreversible harm if mishandled. Proper safety equipment and vigilant precautions are the bedrock of responsible operation, especially within the strict legal landscape of South Africa.

Every laser engraver on steel must be complemented by high-quality laser safety equipment: protective eyewear that filters harmful wavelengths, enclosures to contain laser emissions, and ventilation systems to clear hazardous fumes. These measures are vital, considering the fumes and dust generated during the engraving process—dangerous particles that can linger if not properly managed.

Implementing a comprehensive safety plan is essential. This might include designated safe zones for operation, clear signage warning of laser activity, and strict disposal procedures for waste fumes and debris. Remember, the safety of operators depends on thorough training, including emergency shutdown procedures, ensuring that every hand knows how to respond swiftly when the unexpected occurs.

In South Africa, compliance with local regulations surrounding material handling and laser safety isn’t optional. It is a legal mandate that underpins every successful project involving a laser engraver on steel. Neglecting these protocols doesn’t just risk legal repercussions—it endangers lives. Vigilance, proper equipment, and a culture of safety are the silent guardians that transform a routine task into an act of craftsmanship rooted in responsibility.

0 Comments