Understanding the 800mm Laser Engraver

What is an 800mm Laser Engraver?

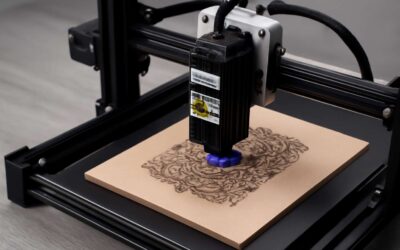

In a world driven by precision and innovation, the 800mm laser engraver emerges as a formidable tool that transcends traditional craftsmanship. Its expansive 800mm engraving area offers artisans and manufacturers the freedom to explore intricate designs without constraint, unlocking new realms of creative expression. This equipment is not merely a device; it’s a gateway to pushing boundaries and reimagining what’s possible in laser technology.

Understanding the 800mm laser engraver entails appreciating its substantial working space, which is pivotal for handling larger projects efficiently. Unlike standard models, this engraver’s size fosters versatility—be it for detailed signage, artistic panels, or bespoke manufacturing. Its robust design ensures durability, while advanced features optimize precision, making it an indispensable asset in South Africa’s thriving manufacturing and artisanal sectors.

To better grasp its capabilities, consider these core attributes:

- Extended engraving area of 800mm, ideal for large-scale projects

- High-resolution precision for detailed craftsmanship

- Durability suited for demanding industrial environments

Key Features and Specifications

Understanding the 800mm laser engraver’s key features and specifications reveals a machine crafted for both precision and expansive creativity. At its core, the 800mm laser engraver boasts an impressive working area that allows artisans and manufacturers to transcend traditional limitations. This generous engraving space is not merely a logistical advantage but a catalyst for innovative design, enabling large-scale projects to come to life with remarkable detail.

One of the most compelling attributes of this device is its high-resolution precision, which ensures every intricate detail is captured with clarity. This level of craftsmanship is vital in industries such as bespoke signage, artistic panel production, and detailed engravings on diverse materials. Its robust construction guarantees durability under demanding industrial conditions, making it a reliable partner for long-term use.

- Extended engraving area of 800mm for large projects

- High-resolution precision for intricate designs

- Durability suited for industrial environments

Moreover, the advanced features integrated into the 800mm laser engraver optimize operational efficiency. From precise control systems to user-friendly interfaces, every element is designed to enhance productivity without sacrificing quality. For professionals in South Africa’s burgeoning craftsmanship sectors, this machine is not just a tool—it’s an extension of their creative vision, pushing boundaries and opening new avenues of innovation in laser technology.

Applications and Industries

In South Africa’s vibrant manufacturing and artisanal sectors, the demand for versatile and reliable engraving solutions continues to surge. The 800mm laser engraver has emerged as a game-changer, enabling creators and industry professionals to realize large-scale projects with unmatched precision and efficiency. Its expansive working area transforms the scope of what’s possible—whether crafting intricate signage or producing detailed artistic panels. This machine’s applications extend far beyond simple engraving, making it an essential tool for industries seeking to push creative boundaries.

From custom furniture makers to promotional product manufacturers, the 800mm laser engraver plays a pivotal role in diverse fields. Its ability to accommodate large materials means projects that once required multiple sessions or manual assembly can now be completed seamlessly. Industries such as giftware, awards, and architectural modeling benefit immensely from its high-resolution capabilities, capturing fine detail that truly elevates finished products. For South African artisans and industrialists alike, this laser engraver is a vital asset in turning innovative ideas into tangible realities.

In essence, the 800mm laser engraver’s versatility allows it to serve a broad spectrum of applications. Whether engraving on wood, acrylic, leather, or metal, its advanced features support complex designs with ease. As local entrepreneurs seek to differentiate their offerings in a competitive market, this machine provides the precision, durability, and expansive capacity needed to stand out. The 800mm laser engraver isn’t just a tool; it’s a catalyst for limitless creativity and industrial excellence across South Africa’s dynamic landscape.

Benefits of Choosing an 800mm Laser Engraver

Large Working Area for Versatile Projects

Harnessing the expansive potential of an 800mm laser engraver transforms the boundaries of creative expression and manufacturing precision. When working with larger projects, the ability to accommodate substantial material sizes without sacrificing detail is invaluable. This large working area means artisans and industry professionals alike can push the envelope, creating intricate, sizable designs in a single setup—eliminating the need for multiple passes that often compromise accuracy and efficiency.

The benefits extend beyond mere size; an 800mm laser engraver’s versatility allows it to handle diverse materials—from thick wood panels to expansive acrylic sheets—making it an indispensable tool across various sectors. Its capacity to engrave and cut in one seamless process ensures that ambitious projects, whether bespoke furniture or large-scale promotional displays, are executed with remarkable precision. For those seeking to elevate their craft or streamline production, the large working area of an 800mm laser engraver is nothing short of a game-changer.

Precision and Detail in Engraving

Precision and attention to detail are what set an 800mm laser engraver apart from smaller or more limited machines. When working on complex designs or intricate patterns, the ability to maintain clarity and sharpness across a large surface becomes essential. This level of accuracy ensures that each project, whether it’s a personalized gift or a commercial product, meets high standards of quality.

Moreover, the expansive working area of an 800mm laser engraver allows for seamless execution of large-scale projects. You won’t have to compromise on detail or join multiple sections together, which can often lead to misalignments. Instead, you get consistent, professional results every time. This combination of size and precision makes the 800mm laser engraver an invaluable asset across industries, from signage to industrial manufacturing.

Choosing an 800mm laser engraver means investing in a machine that offers both versatility and reliability. Its capacity to handle diverse materials and complex designs elevates craftsmanship and productivity alike. When precision and detail are non-negotiable, this type of laser engraver delivers results that speak for themselves!

Efficiency and Speed Benefits

The allure of the 800mm laser engraver lies not only in its expansive canvas but also in its remarkable efficiency and speed. Imagine transforming an intricate design into reality in a fraction of the time it would take with smaller machines—this is the profound advantage of choosing an 800mm laser engraver. Its robust processing capabilities allow for swift execution of large, complex projects, ensuring that creative visions are realized without delay.

This powerhouse machine reduces idle time and accelerates production workflows, making it an indispensable tool for businesses seeking to elevate their craftsmanship with speed and precision. Whether you’re engraving detailed signage or large custom pieces, the 800mm laser engraver’s capacity to work swiftly without compromising quality makes it a game-changer.

Moreover, its ability to handle multiple materials with ease amplifies productivity, allowing operators to switch seamlessly between projects. For those who demand both rapid turnaround and impeccable detail, the 800mm laser engraver is an investment that redefines efficiency.

Cost-Effectiveness for Business Use

The true value of investing in an 800mm laser engraver extends beyond its impressive size. For businesses in South Africa seeking a competitive edge, the cost-effectiveness of this equipment is undeniable. While the initial investment may seem substantial, its ability to expedite production and reduce waste translates into tangible savings over time. The capacity to complete larger projects in less time means fewer resources are tied up in prolonged workflows, allowing for increased throughput without compromising quality.

Additionally, the 800mm laser engraver’s versatility ensures that businesses can diversify their offerings without adding costly machinery. Its compatibility with a wide array of materials opens doors to new markets and custom opportunities, fostering growth and resilience. When considering the long-term return on investment, the efficiency and expansive working area of this machine make it a strategic choice for forward-thinking enterprises eager to maximize profit margins while maintaining impeccable standards.

Types of 800mm Laser Engravers

CO2 Laser Engravers

In the realm of industrial artistry, the 800mm laser engraver stands as a colossal canvas, capable of transforming raw material into intricate masterpieces. Among the myriad options, CO2 laser engravers reign supreme, their versatility and precision making them a favorite for artisans and manufacturers alike. These marvels utilize a carbon dioxide laser beam to etch and carve with extraordinary finesse, ideal for delicate designs or large-scale projects.

What truly sets these machines apart is their adaptability. Whether crafting detailed jewelry, personalized signage, or expansive decorative panels, the 800mm laser engraver offers a broad spectrum of capabilities. The following features exemplify their prowess:

- High-powered laser sources tailored for diverse materials

- Adjustable working depths for nuanced designs

- Robust software compatibility for seamless operation

For industries seeking a harmonious blend of power, precision, and size, the 800mm laser engraver emerges as an indispensable tool—an artist’s brush in a realm where imagination knows no bounds.

Fiber Laser Engravers

When exploring the world of 800mm laser engravers, one cannot overlook the fascinating variety of types available—each tailored to specific needs and materials. Among them, fiber laser engravers have carved out a niche of their own, boasting remarkable speed and precision that make them the darling of industrial artisans. Unlike their CO2 counterparts, fiber laser engravers use a solid-state laser source, which means less maintenance and a longer lifespan—an attractive proposition for those seeking longevity and efficiency.

Fiber laser engravers are particularly adept at marking metals and hard materials with stunning clarity. Their ability to produce crisp, clean engravings often impresses even the most discerning craftsperson. For businesses aiming to optimize productivity, these machines offer a compelling mix of power and speed, especially within the 800mm laser engraver category. Whether you’re engraving jewelry or industrial components, the right fiber laser engraver can transform your workflow and elevate your craftsmanship.

- High-speed operation for rapid production cycles

- Exceptional durability for continuous use

- Precision marking on challenging surfaces

In the grand tapestry of laser engraving technology, fiber laser engravers for the 800mm laser engraver category stand out as a modern marvel—combining sophistication with practicality, all wrapped in a compact yet formidable package. Their ability to handle demanding tasks with finesse makes them an indispensable asset for South African industries looking to push boundaries and redefine quality standards.

Diode Laser Engravers

When it comes to the 800mm laser engraver, the landscape isn’t solely painted with fiber and CO2 options. Enter the realm of diode laser engravers—sleek, efficient, and surprisingly versatile. These machines are often overlooked, yet they pack a punch in their compact frames.

Diode laser engravers for the 800mm laser engraver category are particularly renowned for their affordability and ease of use. They excel in engraving on a wide array of materials, from wood and acrylic to certain plastics. While they may not match the brute strength of fiber lasers, their precision and speed make them a formidable choice for small to medium-sized enterprises.

Consider the following advantages of diode laser engravers:

- Cost-effective initial investment, perfect for startups or hobbyists

- Low maintenance requirements, allowing for uninterrupted workflow

- Compact design, ideal for limited workspace environments

In the grand hierarchy of 800mm laser engraver options, diode laser variants stand out as the nimble, budget-conscious choice—delivering impressive results without demanding a king’s ransom. Their ability to produce detailed engravings on varied substrates ensures they remain a popular choice for South African artisans eager to carve out their niche with a reliable, efficient machine.

Choosing the Right 800mm Laser Engraver

Factors to Consider

Choosing the right 800mm laser engraver is akin to selecting a trusted companion for your creative journey—one that can transform raw materials into works of art with precision and grace. In South Africa’s vibrant craft and manufacturing sectors, the importance of an adaptable, reliable 800mm laser engraver cannot be overstated. It’s not just about size; it’s about understanding the subtle nuances that elevate your projects from ordinary to extraordinary.

When evaluating your options, consider factors such as laser power, software compatibility, and the machine’s build quality. An 800mm laser engraver should seamlessly blend power with finesse, allowing you to undertake intricate designs without sacrificing speed. Additionally, look for models that offer versatility in engraving materials—wood, acrylic, leather, or metal—ensuring your investment aligns with diverse project needs.

- Engraving resolution and detail level

- Ease of operation and maintenance

- Availability of technical support within South Africa

Top Brands and Models

Choosing the right 800mm laser engraver is no small feat, especially when so many brands and models flood the market. In South Africa, where craftsmanship and innovation go hand in hand, selecting a reliable machine can make or break your project. Top brands like Epilog, Glowforge, and OMTech have established reputations for durability and precision, but it’s crucial to match their offerings with your specific needs.

When evaluating models, consider factors such as laser power, software compatibility, and build quality. An 800mm laser engraver from a reputable brand often comes with excellent technical support tailored for South African users, ensuring seamless operation and maintenance. Additionally, many leading models offer versatile engraving capabilities—handling materials like wood, acrylic, leather, and even metal—making them well-suited for diverse industries.

- Research user reviews and local distributor support

- Compare specifications for engraving resolution and detail level

- Assess ease of operation and maintenance features

Ultimately, investing in a top-tier 800mm laser engraver from trusted brands guarantees not just high-quality results but also peace of mind as you scale your creative or manufacturing enterprise in South Africa.

Installation and Operation Tips

Setup Requirements

Setting up an 800mm laser engraver isn’t just about plugging in and pressing a button; it’s a meticulous process that demands precision and patience. Proper installation can dramatically influence your engraving quality and operational lifespan. Ensuring a stable, vibration-free surface is essential—any wobble can compromise the intricate details that make laser engraving so compelling. Additionally, adequate ventilation isn’t optional; it’s a necessity to prevent fumes from accumulating and affecting the laser’s performance.

Before operation, verify that your workspace meets the setup requirements—ample space for the large working area of the 800mm laser engraver, proper electrical connections, and safety measures in place. Many users overlook the importance of aligning the laser head correctly, which can lead to uneven engraving and wasted material. Remember, a well-calibrated setup is the secret to flawless results. To streamline your workflow, consider creating a checklist that includes:

- Ensuring proper grounding of the machine

- Checking lens and mirror cleanliness

- Verifying software compatibility and updates

Mastering the installation and operation setup for an 800mm laser engraver is the first step toward unlocking its full potential, transforming raw materials into art with supernatural precision and speed.

Safety Measures

Installing and operating an 800mm laser engraver isn’t a task for the faint of heart, but with the right safety measures, it becomes a rewarding endeavor. Safety first — because a laser malfunction or accidental exposure can turn your workshop into a no-go zone faster than you can say “laser beam.” Always wear appropriate protective eyewear and ensure your workspace is well-ventilated to prevent fume buildup, which is especially critical when working with large-scale engravers.

To keep things smooth and hazard-free, consider implementing a few key safety tips. For instance, proper grounding of your 800mm laser engraver is non-negotiable; static or electrical faults are the last thing you want during operation. Regularly checking the lens and mirror cleanliness is also vital — dirty optics can cause misfires or uneven engraving, wasting materials and time.

- Ensure your workspace has an emergency stop button accessible at all times.

- Keep flammable materials away from the laser’s path.

- Never leave the machine unattended while it’s operating.

By respecting these safety measures, you’ll not only safeguard yourself but also extend the lifespan of your 800mm laser engraver, ensuring it continues to transform raw materials into masterpieces with supernatural speed and pinpoint accuracy. After all, a safe setup is the foundation of successful laser engraving!

Maintenance and Troubleshooting

Getting your 800mm laser engraver up and running requires more than just plugging it in. Proper installation is crucial for optimal performance and safety. Make sure your workspace has a sturdy, level surface to support the large footprint of the 800mm laser engraver. Before operation, double-check all connections, especially power and focus alignment, to prevent costly misfires. Regular maintenance is vital; clean the lens and mirrors with specialized cloths to maintain precision and avoid uneven engraving. Lubricate moving parts periodically to reduce wear and tear, ensuring longevity. Troubleshooting common issues like inconsistent engraving or laser misfires often comes down to simple fixes—such as recalibrating the focus or checking for debris blocking the laser path. If problems persist, consult your manufacturer’s manual or contact technical support to avoid causing further damage. Remember, a well-maintained 800mm laser engraver is the cornerstone of consistent, high-quality results in every project.

Software and Compatibility

When it comes to operating an 800mm laser engraver, seamless software compatibility transforms a daunting task into a graceful ballet of precision and efficiency. An intuitive interface paired with robust design software ensures your creative visions translate flawlessly onto your chosen medium. It’s worth noting that not all software plays nicely with the 800mm laser engraver, so selecting a platform that supports your specific model can save hours of frustration.

For optimal results, ensure your software supports common file formats—think SVG, DXF, and AI—so you can import designs effortlessly. Compatibility with operating systems like Windows and macOS broadens your options, making setup a breeze. Remember, the right software not only enhances your workflow but also unlocks the full potential of your 800mm laser engraver’s large workspace.

- Check for firmware updates regularly

- Verify your software’s support for advanced features like auto-focus and multi-layer engraving

Enhancing Efficiency with 800mm Laser Engravers

Automation and Workflow Integration

Maximizing productivity with an 800mm laser engraver hinges on seamless automation and workflow integration. In today’s fast-paced manufacturing environment, efficiency isn’t just a luxury — it’s a necessity. An 800mm laser engraver equipped with intelligent automation features can significantly reduce manual intervention, allowing operators to focus on design innovation rather than operational logistics.

Advanced software solutions enable synchronized workflows, where tasks like design loading, job scheduling, and quality control are streamlined. For instance, integrating your 800mm laser engraver with a centralized management system ensures real-time tracking and quick adjustments, minimizing downtime. As a result, businesses can handle larger volumes without sacrificing precision or speed.

- Automated job queuing

- Real-time status updates

- Efficient material handling

This holistic approach to workflow integration transforms the 800mm laser engraver from a simple tool into a powerhouse of operational excellence, ultimately boosting throughput and profitability in competitive markets like South Africa’s bespoke craftsmanship and industrial sectors.

Design Optimization Tips

Maximizing the potential of an 800mm laser engraver hinges on smart design optimization. When every millimeter counts, fine-tuning your designs for the large working area can dramatically boost efficiency. Precise layout planning ensures material is used optimally, reducing waste and downtime—crucial factors in competitive markets like South Africa’s bespoke craftsmanship sector.

To elevate your workflow, consider integrating intricate designs that leverage the engraver’s expansive 800mm workspace. This not only speeds up production but also enhances the quality of each piece.

- Use vector graphics for sharp, detailed engravings

- Pre-arrange multiple items for batch processing

- Optimize engraving paths to minimize movement

Such strategic adjustments turn a standard 800mm laser engraver into a powerhouse of productivity. When design optimization is paired with the right software, operators can achieve unparalleled precision and speed—transforming complex projects into seamless realities that captivate clients and elevate business growth.

Material Handling and Storage

Maximizing efficiency with an 800mm laser engraver requires more than just technical prowess; it demands strategic material handling and meticulous storage solutions. In a bustling South African craft market, where time is money and precision commands premium prices, optimizing how materials are organized can significantly reduce downtime. Proper storage not only preserves the quality of your substrates but also accelerates workflow, enabling seamless transitions between projects.

Implementing a systematic approach can involve categorizing materials by size, type, or project priority. For instance, an organized shelving system for different types of wood, acrylic, or leather ensures that your 800mm laser engraver is always ready to go—eliminating the delays caused by searching or sorting materials mid-production. Additionally, pre-cutting and stacking materials in batches streamlines the process, making batch processing with an 800mm laser engraver more efficient than ever.

Consider adopting a few key practices:

- Designate specific zones for raw materials and finished pieces

- Use labels and clear signage to speed up retrieval

- Maintain a catalog or inventory system for quick reference

By refining material handling and storage, operators can fully harness the expansive capabilities of an 800mm laser engraver, transforming it into a true pillar of productivity. Such meticulous organization not only optimizes space but also elevates the overall quality and consistency of each engraved masterpiece—crucial in a competitive landscape where every detail matters.

Cost Analysis and ROI

Initial Investment vs. Long-Term Benefits

Investing in an 800mm laser engraver might seem like a hefty upfront expense, but the long-term benefits often outweigh the initial cost. When considering the cost analysis, it’s essential to weigh the initial investment against potential returns. An 800mm laser engraver can drastically cut production times and elevate the quality of your work, leading to increased customer satisfaction and repeat business. The true magic lies in the ROI (return on investment), which becomes evident as your workflow becomes more efficient and your product offerings expand. For example, with a larger working area, you can take on bigger projects that previously required outsourcing, saving both time and money.

Long-term benefits include reduced material waste, higher precision, and the ability to handle diverse materials seamlessly. To visualize this, think of the 800mm laser engraver as a silent partner that works tirelessly, turning raw materials into polished masterpieces. Over years, its durability and low maintenance costs can make the initial expense look trivial. For business owners, this means a smarter, more profitable operation—turning a hefty investment into a lucrative enterprise. Remember, the right 800mm laser engraver is not just a purchase; it’s a strategic move toward sustainable growth and competitive edge in today’s bustling market!

Operational Costs

When evaluating the true cost of an 800mm laser engraver, it’s crucial to consider operational expenses alongside the initial purchase price. While the upfront investment may seem substantial, the long-term savings and increased productivity can make it a wise financial decision. For instance, the energy consumption of an 800mm laser engraver is generally optimized to deliver high output with minimal power use, reducing ongoing utility bills. Additionally, maintenance costs tend to be lower due to the durability and reliability of modern models, which are designed to operate seamlessly over years.

To understand the financial impact better, many businesses perform a detailed cost analysis. This often includes examining factors such as:

- Material waste reduction through high precision engraving

- Time savings in production cycles

- Potential for taking on larger or more complex projects

These elements directly influence the ROI (return on investment) of an 800mm laser engraver. As workflow efficiency improves, so does the ability to generate higher revenue streams—turning what initially appears as a significant expenditure into a lucrative asset. For business owners eyeing long-term growth, investing in an 800mm laser engraver is often a strategic move that pays dividends in both productivity and profitability.

Expected Return on Investment

In the labyrinth of manufacturing investments, the true worth of an 800mm laser engraver emerges only when scrutinized through the lens of cost analysis and expected ROI. While the initial expenditure can seem daunting, the real question lies in how this powerful tool transforms operational efficiency into tangible profits. The sleek precision of an 800mm laser engraver not only minimizes material waste but accelerates production cycles, delivering a dual boon of savings and speed that few other machines can match.

By meticulously evaluating variables such as energy consumption, maintenance costs, and project scalability, businesses can unveil a clearer picture of long-term benefits. An investment in an 800mm laser engraver often manifests as a strategic move that amplifies revenue streams through the ability to undertake larger, more complex projects with unwavering accuracy. The return on investment becomes evident as workflow efficiency elevates, turning what appears as a hefty upfront cost into a lucrative asset that fosters sustained growth and competitive advantage.

Future Trends in Large-Format Laser Engraving

Technological Innovations

The horizon of large-format laser engraving is shimmering with visionary possibilities, as technological innovations promise to redefine precision and efficiency. The advent of the 800mm laser engraver heralds a new era where colossal working areas meet unparalleled accuracy, empowering artisans and industries alike to realize their grandest visions. As laser technology advances, we see the emergence of smarter systems—integrating artificial intelligence to optimize engraving paths and minimize material wastage, all while enhancing the finesse of intricate designs.

Future trends point towards seamless automation and workflow integration, transforming the 800mm laser engraver from a mere tool into a central hub of creative production. Imagine a world where the engraver communicates effortlessly with design software, adjusting parameters in real time, and executing massive projects with minimal human intervention. Additionally, innovations in material handling and storage will extend the lifespan of the laser components, making large-scale projects more sustainable and cost-effective. It’s an inspiring vision—where innovation and artistry converge in a symphony of technological prowess.

New Market Opportunities

As technological horizons expand, the future of large-format laser engraving is poised to unlock extraordinary market opportunities. The 800mm laser engraver stands at the forefront of this revolution, transforming creative landscapes and industrial workflows alike. With the integration of smarter systems, these engravers will increasingly communicate seamlessly with design software, enabling real-time adjustments and reducing material wastage. This evolution not only accelerates production but also elevates the quality of intricate designs, making large-scale projects more feasible than ever before.

Emerging trends suggest a shift toward fully automated production environments. Imagine an 800mm laser engraver that autonomously manages complex projects, optimizing parameters instantaneously while interfacing effortlessly with other manufacturing systems. The potential for expanding into new markets—such as bespoke signage, large-format décor, or custom architectural elements—is immense. As the technology matures, we can expect innovations like advanced material handling and extended component durability, which will significantly reduce operational costs and increase sustainability.

Sustainable and Eco-Friendly Practices

As the world gravitates toward eco-conscious innovation, the future of large-format laser engraving is undeniably green—quite literally. The advent of sustainable practices in laser technology isn’t just a trend; it’s fast becoming the standard. The 800mm laser engraver, with its expansive working area, is uniquely positioned to spearhead this environmentally friendly revolution. By optimizing energy consumption and minimizing waste, these machines are carving a path toward greener manufacturing processes.

One promising trend is the integration of eco-friendly materials and dyes that reduce harmful emissions during engraving. Additionally, advancements in laser efficiency mean less power is used for more impressive results. Companies are now exploring the use of recycled substrates and biodegradable finishes, making large-scale projects not just visually stunning but also planet-positive. A simple yet impactful step is adopting laser systems that incorporate recycled components, reducing the carbon footprint associated with manufacturing the 800mm laser engraver itself.

Furthermore, sustainability extends beyond materials. The design of the 800mm laser engraver itself is evolving to include energy-saving modes and longer-lasting components—think extended laser diode life and self-cleaning optics. These innovations not only slash operational costs but also align with global efforts to reduce electronic waste. Embracing these eco-friendly practices ensures that businesses can enjoy the benefits of large-format laser engraving while keeping their environmental conscience intact.

0 Comments